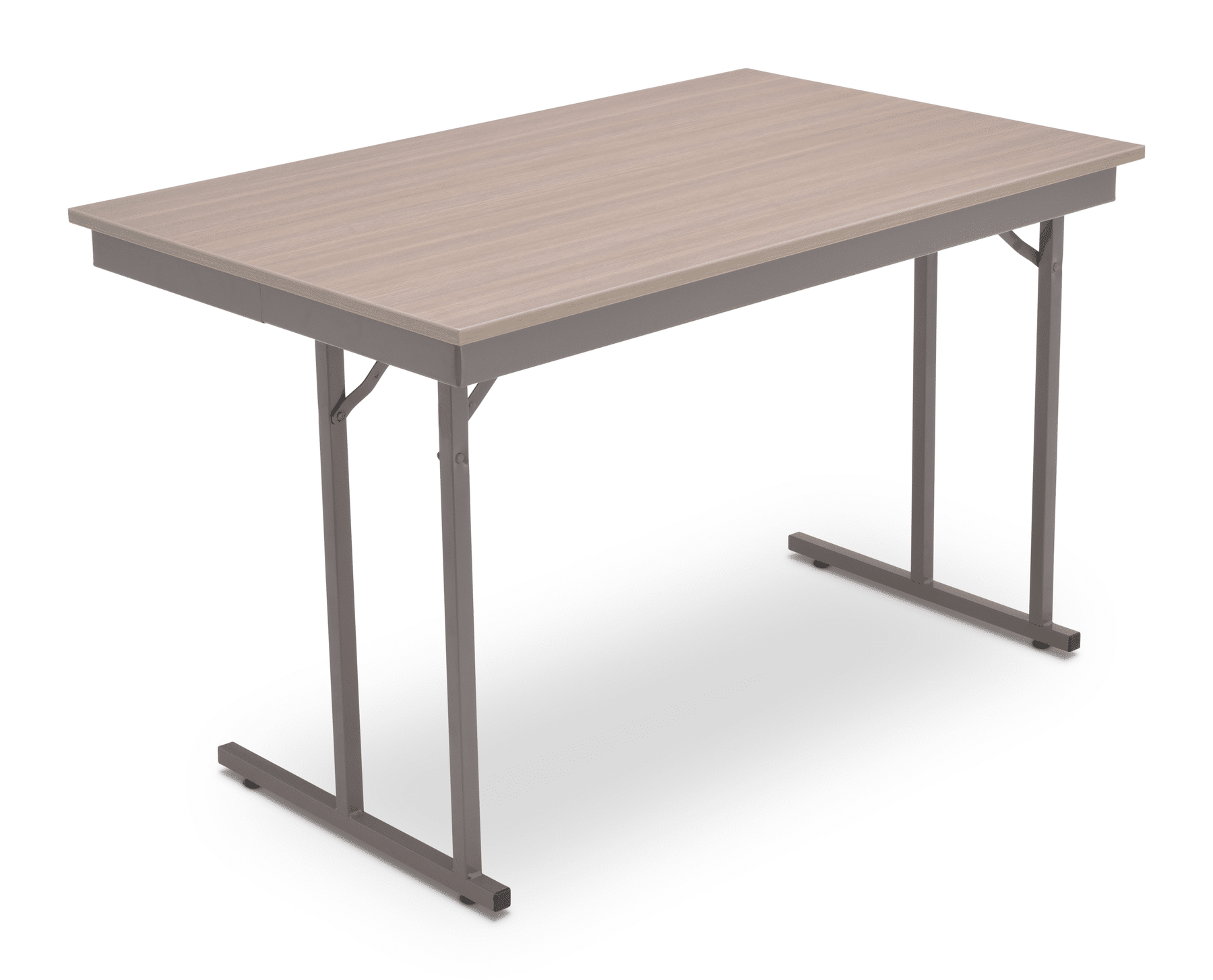

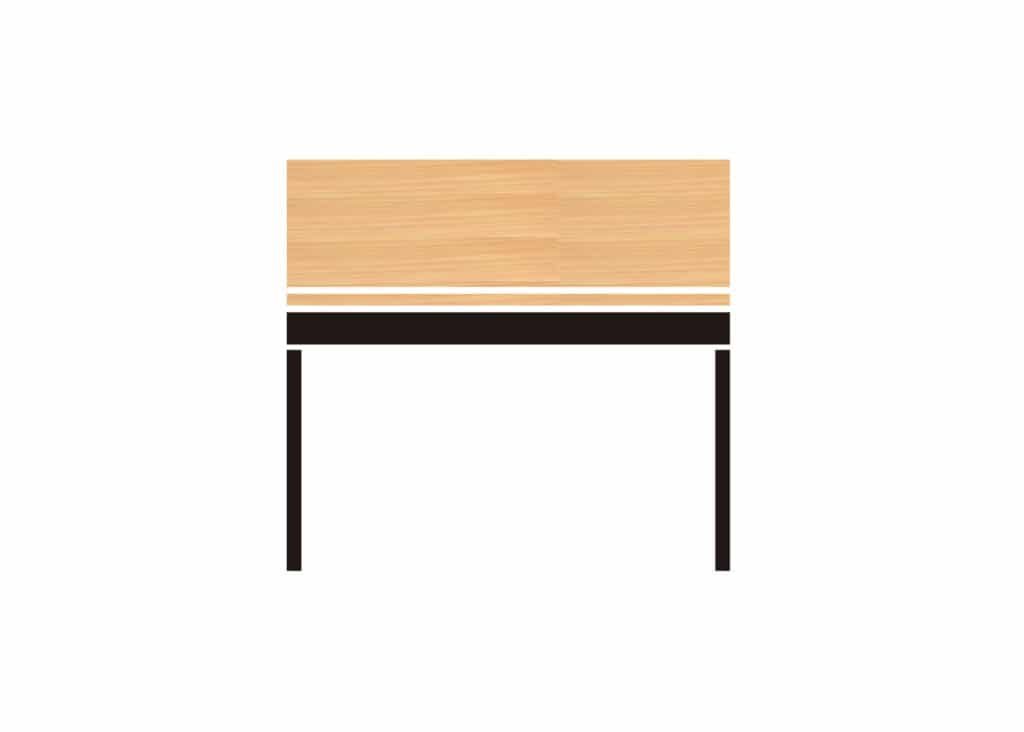

Folding Workstation

$0.00

Folding Workstation

- Economical workstation

- Fully assembled- Just unfold for use

- ¾” top available in HPL or TFL laminates

- Customizable finishes

- Product Details

- Features & Options

- Specifications & Materials

- Color Selections - In Stock Options

- Custom Wilsonart Options

- Assembly

- Cut Sheet

Product Details

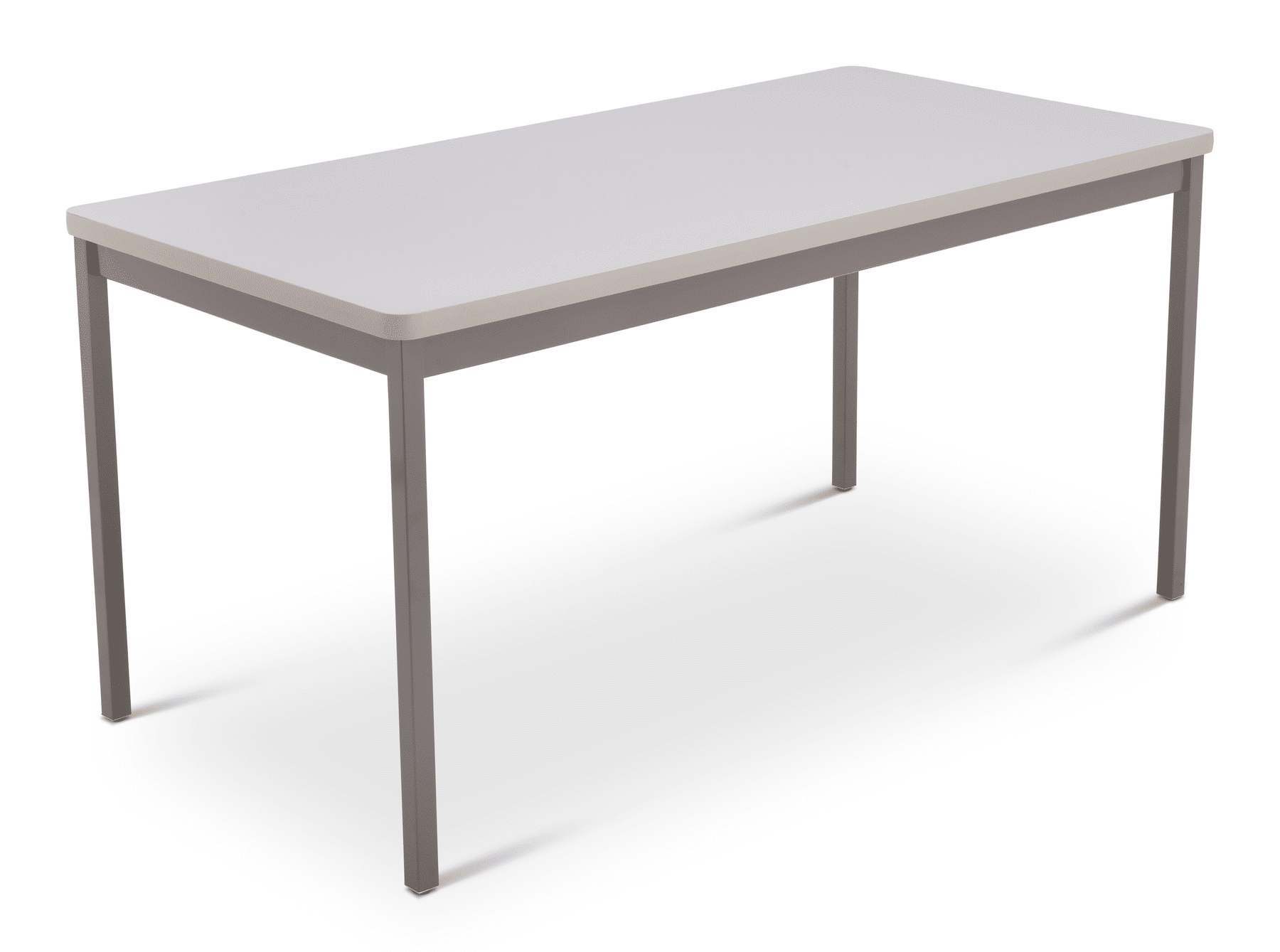

The Folding Workstation easily sets up or stores. Barricks’ folding workstation has several top options that include ¾” particleboard core or ¾” plywood core each with high pressure laminate (HPL) top surface and moisture resistant bottom surface, or ¾” particleboard core thermally fused laminate (TFL) on top and bottom surfaces, all finished with a protective T-mold or 3mm edge. The Folding Workstation has two 1” sq 18 gauge steel vertical supports welded to 1” sq 18 gauge steel base. Each leg has two compression locks securing open position. Adjustable levelers ensure proper positioning and alignment on uneven floors. Barricks stocks 30 HPL and 16 TFL options to create your customized design.

Folding Workstation- 30″ Height

HPL Top Particleboard Core

| Size | T-Mold Model # | 3mm Model # | Weight |

| 30×48 | FCW-3048-PT | FCW-3048-PM | TBD |

HPL Top Plywood Core

| Size | T-Mold Model # | 3mm Model # | Weight |

| 30×48 | FCW-3048-WT | FCW-3048-WM | TBD |

TFL Top Particleboard Core

| Size | T-Mold Model # | 3mm Model # | Weight |

| 30×48 | FCW-3048-TT | FCW-3048-TM | TBD |

Features & Options

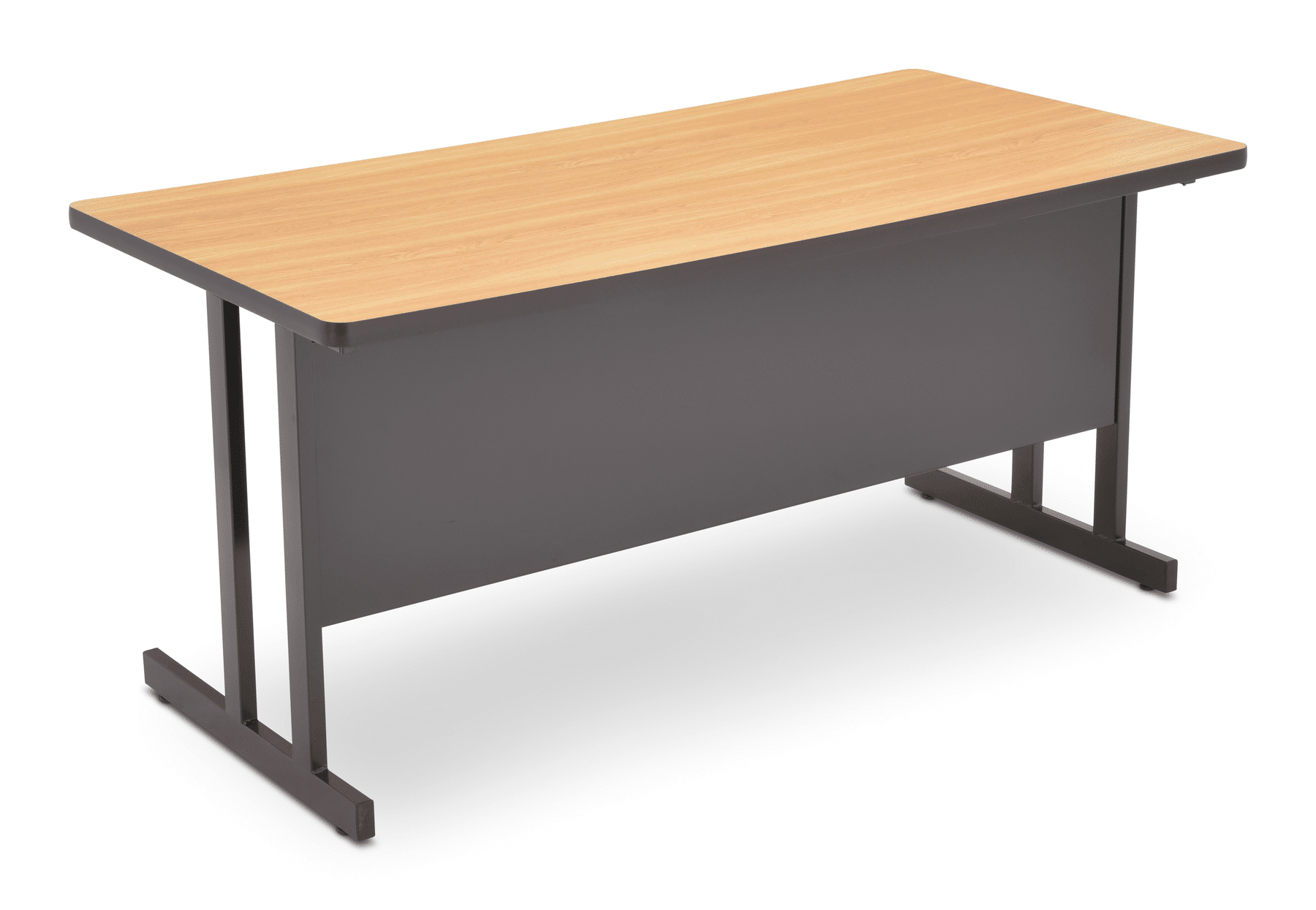

Strong, Rigid Apron

18 gauge 2 ¼” h steel apron with rolled bottom edge for added strength, attached with coarse, deep threaded screws designed specifically for particleboard and plywood.

T-mold Edge

Rounded Corners

Rounded plastic molding secures to top’s edge using friction barb; provides impact protection to sides. T-mold edged tables have rounded corners.

3mm Edge

Square Corners

3mm (1/8”) thick flat plastic edging machine glued, sealing edge; provides impact protection to top’s sides. 3mm edged tables have square corners.

Compression Lock

Compression lock secures table leg in locked open position. Each leg has two compression locks, connecting cross bracing and locking bar.

Adjustable Levelers

Adjustable levelers provide stability on uneven floors and ensure proper height positioning to adjoining tables.

Options:

Specification & Materials

Top:

HPL Particle Board Core- 3/4″ particleboard core with high pressure laminate (HPL) top surface, moisture resistant backer bottom surface finished with a protective edge option- t-mold or 3mm.

HPL Plywood Core- 3/4″ plywood core with high pressure laminate (HPL) top surface, moisture resistant backer bottom surface finished with a protective edge option- t-mold or 3mm.

TFL– 3/4″ particleboard core, thermally fused laminate (TFL) on top and bottom surface finished with a protective edge option- t-mold or 3mm.

Edging:

T-mold- an extruded plastic edging in the shape of a “T”. The stem part is barbed and inserted into a slot in the core board. The friction barbs prevent the t-mold from coming out of the core. T-mold external surface is slightly rounded and provides protection against impacts to side. T-mold is an economical edge.

3mm- an extruded 3mm (1/8”) plastic that is machine glued to panel sides sealing edge, then machine trimmed to fit panel thickness. Edging provides protection against impact to sides. 3mm corners are square and more expensive than using T-mold.

Apron:

Table apron is a strong rigid 2 1/4″ 18 gauge rolled formed edge steel apron attached with specified particleboard/ plywood coarse thread screws.

Legs:

Table legs are 1″ sq 18 gauge steel. Each leg has two compression locks securing open position. Adjustable levelers ensure proper positioning and alignment on uneven floors.

Color Selections - In Stock Options

HPL Selections- Particleboard/ Plywood

Wilsonart

Selections

TFL Selections- Particleboard

Paint Selections - Apron/ Leg/ Lock

T-mold Edge (Table will have rounded corners)

* Indicates edge is available only in ¾”.

3mm Edge (Table will have square corners)

Wilsonart - Custom Order Laminates

Contact Sales/ Customer Service for selection of Wilsonart alternatives.

1-800-404-6843

Assembly

No assembly required for this table. Just remove from box, unfold legs, and use.

Cut Sheet

Recommended Ash Configurations

Edge: Ash (1)

Paint: Black

Edge: Ash (1)

Paint: Charcoal

Edge: Ash (1)

Paint: Gray

Edge: Ash (1)

Paint: Platinum

Edge: Ash (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

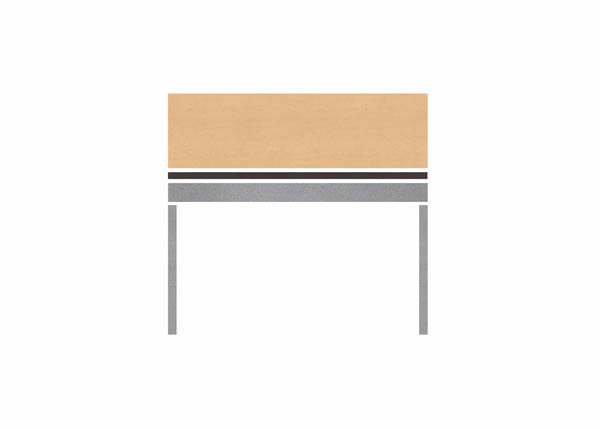

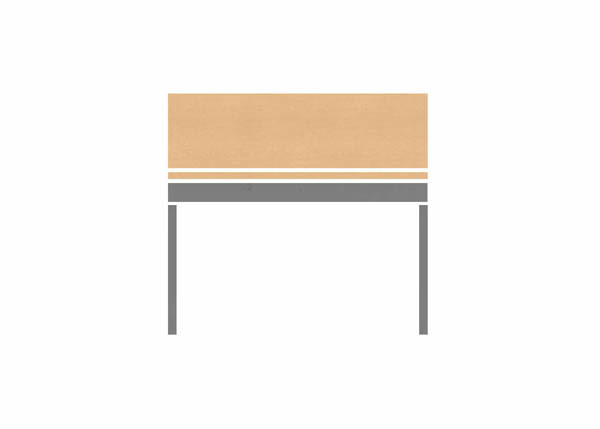

Recommended Asian Sand Configurations

Edge: Asian Sand (3)

Paint: Black

Edge: Asian Sand (3)

Paint: Charcoal

Edge: Asian Sand (3)

Paint: Gray

Edge: Asian Sand (3)

Paint: Platinum

Edge: Asian Sand (3)

Paint: Metallic Silver

Edge: Asian Sand (3)

Paint: Tan

Edge: Black (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Tan

Edge: Gray (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Biltmore Cherry Configurations

Edge: Biltmore Cherry (1)

Paint: Tan

Edge: Biltmore Cherry (1)

Paint: Black

Edge: Biltmore Cherry (1)

Paint: Brown

Edge: Biltmore Cherry (1)

Paint: Platinum

Edge: Biltmore Cherry (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Black Configurations

Edge: Gray (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Black

Edge: Gray (1)

Paint: Gray

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Gray

Edge: Gray (1)

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Bullseye Red Configurations

Edge: Gray (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Gray

Edge: Putty (1)

Paint: Metallic Silver

Edge: Putty (1)

Paint: Putty

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Cafelle Configurations

Edge: Cafelle (1)

Paint: Black

Edge: Cafelle (1)

Paint: Charcoal

Edge: Cafelle (1)

Paint: Platinum

Edge: Cafelle (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Cocobala Configurations

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

Edge: Cocobala (1)

Paint: Black

Edge: Cocobala (1)

Paint: Brown

Edge: Cocobala (1)

Paint: Platinum

Edge: Cocobala (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Brown

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Designer White Configurations

Edge: White (1)

Paint: Brown

Edge: White (1)

Paint: Charcoal

Edge: White (1)

Paint: Gray

Edge: White (1)

Paint: Platinum

Edge: White (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Gray (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: White (1)

Paint: Black

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Dove Grey Configurations

Edge: Black (1)

Paint: Black

Edge: Gray (1)

Paint: Black

Edge: Black (1)

Paint: Gray

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Empire Mahogany Configurations

Edge: Empire Mahogany (1)

Paint: Platinum

Edge: Empire Mahogany (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Metallic Silver

Edge: Empire Mahogany (1)

Paint: Black

Edge: Empire Mahogany (1)

Paint: Charcoal

Edge: Empire Mahogany (1)

Paint: Gray

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended English Oak Configurations

Edge: Brown (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

Edge: English Oak (1)

Paint: Black

Edge: English Oak (1)

Paint: Brown

Edge: English Oak (1)

Paint: Platinum

Edge: English Oak (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Brown

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Figured Mahogany Configurations

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Metallic Silver

Edge: Figured Mahogany (1)

Paint: Black

Edge: Figured Mahogany (1)

Paint: Charcoal

Edge: Figured Mahogany (1)

Paint: Gray

Edge: Figured Mahogany (1)

Paint: Platinum

Edge: Figured Mahogany (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Fonthill Pear Configurations

Edge: Fonthill Pear (1)

Paint: Black

Edge: Fonthill Pear (1)

Paint: Brown

Edge: Fonthill Pear (1)

Paint: Platinum

Edge: Fonthill Pear (1)

Paint: Metallic Silver

Edge: Fonthill Pear (1)

Paint: Tan

Edge: Black (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Fusion Maple Configurations

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Fusion Maple (1)

Paint: Gray

Edge: Fusion Maple (1)

Paint: Black

Edge: Fusion Maple (1)

Paint: Brown

Edge: Fusion Maple (1)

Paint: Metallic Silver

Edge: Fusion Maple (1)

Paint: Tan

Edge: Fusion Maple (1)

Paint: Charcoal

Edge: Fusion Maple (1)

Paint: Platinum

Edge: Black (1)

Paint: Black

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Glacier Configurations

Edge: Glacier (1)

Paint: Platinum

Edge: Glacier (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Glacier (1)

Paint: Black

Edge: Glacier (1)

Paint: Charcoal

Edge: Glacier (1)

Paint: Gray

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Graphite Nebula Configurations

Edge: Black (1)

Paint: Metallic Silver

Edge: Graphite Nebula (1)

Paint: Black

Edge: Graphite Nebula (1)

Paint: Charcoal

Edge: Graphite Nebula (1)

Paint: Gray

Edge: Graphite Nebula (1)

Paint: Platinum

Edge: Graphite Nebula (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Black

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Gray

Edge: Black (1)

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Grey Nebula Configurations

Edge: Black (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Charcoal

Edge: Grey Nebula (1)

Paint: Charcoal

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Gray

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

Edge: Grey Nebula (1)

Paint: Black

Edge: Gray (1)

Paint: Black

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Platinum

Edge: Gray (1)

Paint: Metallic Silver

Edge: Grey Nebula (1)

Paint: Gray

Edge: Grey Nebula (1)

Paint: Platinum

Edge: Grey Nebula (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Hunter Green Configurations

Edge: Gray (1)

Paint: Black

Edge: Gray (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Gray

Edge: Black (1)

Paint: Metallic Silvdr

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Marigold Configurations

Edge: Gray (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Brown

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

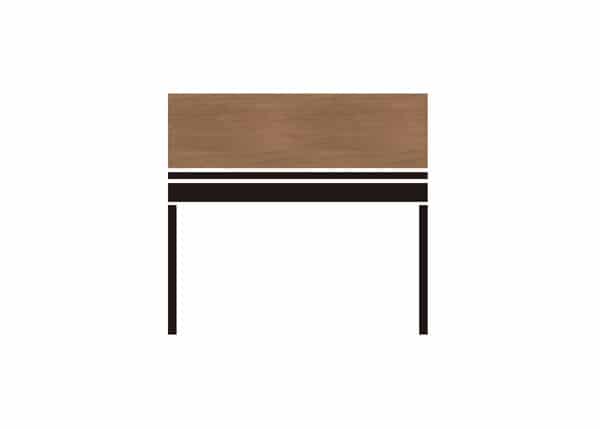

Recommended Montana Walnut Configurations

Edge: Black (1)

Paint: Metallic SIlver

Edge: Brown (1)

Paint: Metallic SIlver

Edge: Montana Walnut (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Brown

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Tan

Edge: Brown (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Tan

Edge: Montana Walnut (1)

Paint: Platinum

Edge: Montana Walnut (1)

Paint: Tan

Edge: Montana Walnut (1)

Paint: Black

Edge: Montana Walnut (1)

Paint: Brown

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Nepal Teak Configurations

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Tan

Edge: Nepal Teak (1)

Paint: Black

Edge: Nepal Teak (1)

Paint: Brown

Edge: Nepal Teak (1)

Paint: Charcoal

Edge: Nepal Teak (1)

Paint: Platinum

Edge: Nepal Teak (1)

Paint: Metallic Silver

Edge: Nepal Teak (1)

Paint: Tan

Edge: Brown (1)

Paint: Charcoal

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Persian Blue Configurations

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Putty (1)

Paint: Putty

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Pewter Brush Configurations

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Gray

Edge: Black (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Black

Edge: Gray (1)

Paint: Charcoal

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Quartered Oak Configurations

Edge: Black

Paint: Black

Edge: Brown

Paint: Brown

Edge: Brown

Paint: Platinum

Edge: Brown

Paint: Tan

Edge: Putty

Paint: Metallic Silver

Edge: Putty

Paint: Putty

Edge: Quarter Oak

Paint: Black

Edge: Quarter Oak

Paint: Brown

Edge: Quarter Oak

Paint: Metallic Silver

Edge: Quarter Oak

Paint: Platinum

Edge: Quarter Oak

Paint: Putty

Edge: Quarter Oak

Paint: Tan

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended River Cherry Configurations

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Brown

Edge: River Cherry (3)

Paint: Tan

Edge: River Cherry (3)

Paint: Platinum

Edge: Brown (1)

Paint: Black

Edge: Black (1)

Paint: Platinum

Edge: River Cherry (3)

Paint: Brown

Edge: River Cherry (3)

Paint: Black

Edge: Black (1)

Paint: Black

Edge: River Cherry (3)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Tan

Edge: Brown (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Shaker Cherry Configurations

Edge: Brown (1)

Paint: Metallic Silver

Edge: Shaker Cherry (1)

Paint: Black

Edge: Shaker Cherry (1)

Paint: Brown

Edge: Shaker Cherry (1)

Paint: Platinum

Edge: Shaker Cherry (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Skyline Walnut Configurations

Edge: Skyline Walnut (3)

Paint: Black

Edge: Skyline Walnut (3)

Paint: Charcoal

Edge: Skyline Walnut (3)

Paint: Platinum

Edge: Skyline Walnut (3)

Paint: Metallic Silver

Edge: Black (1)

Paint: Gray

Edge: Gray (1)

Paint: Gray

Edge: Skyline Walnut (3)

Paint: Gray

Edge: Black (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Platinum

Edge: Gray (1)

Paint: Black

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Solar Oak Configurations

Edge: Brown (1)

Paint: Tan

Edge: Solar Oak (1)

Paint: Platinum

Edge: Solar Oak (1)

Paint: Black

Edge: Solar Oak (1)

Paint: Brown

Edge: Solar Oak (1)

Paint: Metallic Silver

Edge: Solar Oak (1)

Paint: Tan

Edge: Black (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Studio Teak Configurations

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

Edge: Studio Teak (3)

Paint: Black

Edge: Studio Teak (3)

Paint: Brown

Edge: Studio Teak (3)

Paint: Charcoal

Edge: Studio Teak (3)

Paint: Platinum

Edge: Studio Teak (3)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Charcoal

Edge: Black (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Truffle Configurations

Edge: Truffle (1)

Paint: Black

Edge: Truffle (1)

Paint: Brown

Edge: Truffle (1)

Paint: Platinum

Edge: Truffle (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Wild Cherry Configurations

Edge: Black (1)

Paint: Metallic Silver

Edge: Black (1)

Paint: Black

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Metallic Silver

Edge: Wild Cherry (1)

Paint: Black

Edge: Wild Cherry (1)

Paint: Brown

Edge: Wild Cherry (1)

Paint: Platinum

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Metallic Silver

Edge: Wild Cherry (1)

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Windsor Mahogany Configurations

Edge: Brown (1)

Paint: Platinum

Edge: Brown (1)

Paint: Metallic Silver

Edge: Windsor Mahogany (1)

Paint: Black

Edge: Windsor Mahogany (1)

Paint: Brown

Edge: Windsor Mahogany (1)

Paint: Platinum

Edge: Windsor Mahogany (1)

Paint: Metallic Silver

Edge: Windsor Mahogany (1)

Paint: Tan

Edge: Black (1)

Paint: Black

Edge: Black (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Brown

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Hardrock Maple Configurations

Edge: Maple (1)

Paint: Tan

Edge: Brown (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Maple (1)

Paint: Gray

Edge: Maple (1)

Paint: Black

Edge: Maple (1)

Paint: Metallic Silver

Edge: Maple (1)

Paint: Charcoal

Edge: Maple (1)

Paint: Gray

Edge: Gray (1)

Paint: Platinum

Edge: Black (1)

Paint: Black

Edge: Maple (1)

Paint: Brown

Edge: Brown (1)

Paint: Brown

Edge: Brown (1)

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Manitoba Maple Configurations

Edge: Maple (1)

Paint: Tan

Edge: Maple (1)

Paint: Brown

Edge: Brown (1)

Paint: Brown

Edge: Black (1)

Paint: Metallic Silver

Edge: Maple (1)

Paint: Black

Edge: Maple (1)

Paint: Gray

Edge: Gray (1)

Paint: Metallic Silver

Edge: Gray (1)

Paint: Gray

Edge: Brown (1)

Paint: Metallic Silver

Edge: Brown (1)

Paint: Platinum

Edge: Maple (1)

Paint: Metallic Silver

Edge: Maple (1)

Paint: Tan

Edge: Maple (1)

Paint: Charcoal

Edge: Maple (1)

Paint: Gray

Edge: Gray

Paint: Metallic Silver

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Recommended Volunteer Walnut Configurations

Edge: Black

Paint: Metallic Silver

Edge: Brown

Paint: Brown

Edge: Brown

Paint: Platinum

Edge: Brown

Paint: Metallic Silver

Edge: Brown

Paint: Tan

Edge: Volunteer Walnut

Paint: Brown

Edge: Volunteer Walnut

Paint: Black

Edge: Volunteer Walnut

Paint: Platinum

Edge: Volunteer Walnut

Paint: Metallic Silver

Edge: Volunteer Walnut

Paint: Tan

Edge: Brown

Paint: Black

Edge: Black

Paint: Black

Edge: Black

Paint: Brown

Edge: Black

Paint: Platinum

(1) Available in T-mold- rounded corners and 3mm edges- square corners.

(2) Available only in T-mold edge- rounded corners.

(3) Available only in 3mm edge- square corners.

Similar products

-

Sierra Series

Call for Price -

130 Series

$0.00 -

5100 Series

Call for Price -

Deluxe Utility Series

Call for Price