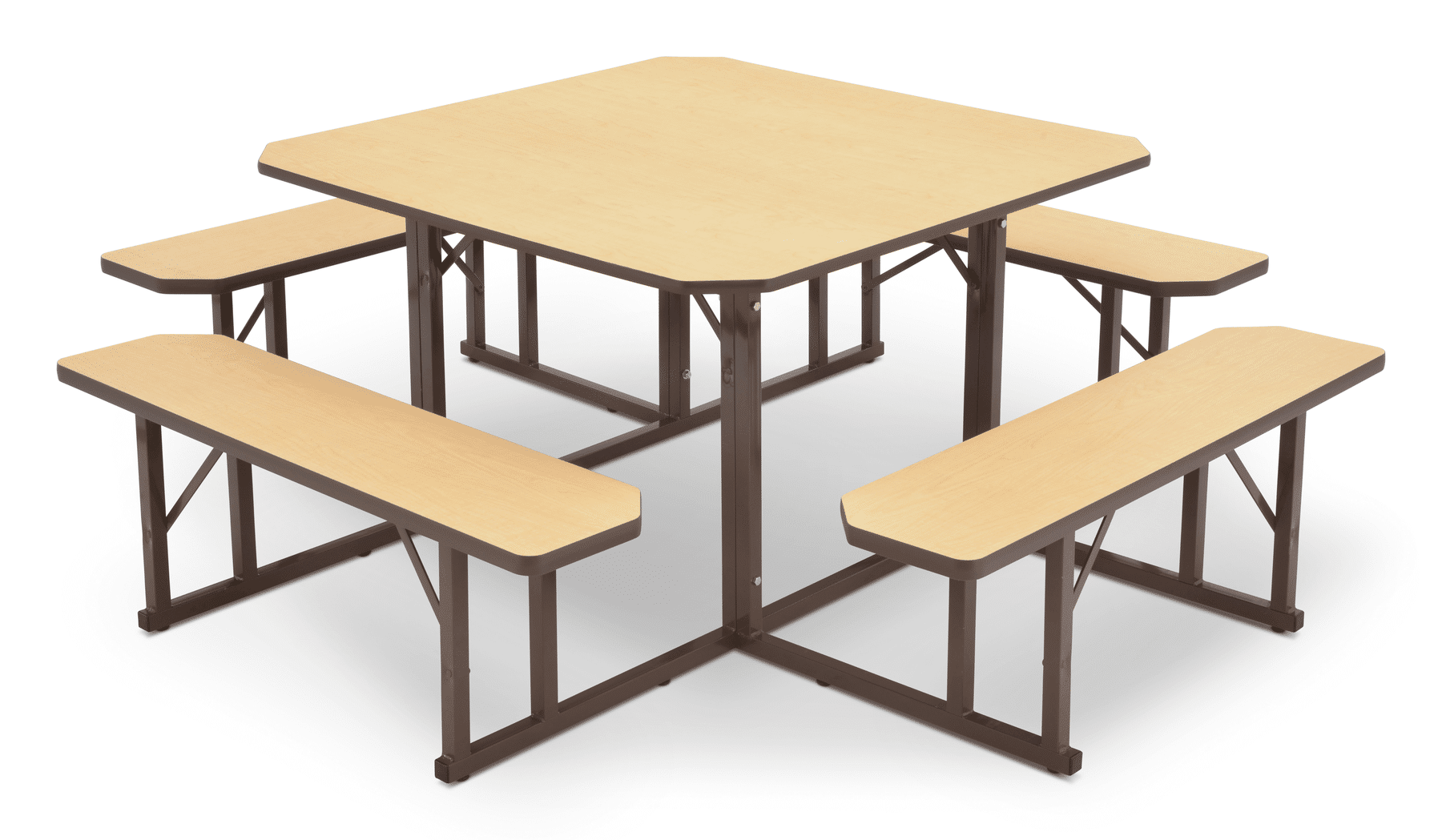

Cafe Top Series – Square

$0.00

Square Tabletop

- Barricks offers 4 Square top size options from which to choose

- Café square top has three construction options:

- 1 ¼” HPL top surface, particleboard core, t-mold edge

- 1 ¼” HPL top surface, particleboard core, 3mm edge

- 1” 3DL seamless top surface/edge, MDF core

- Available in HPL laminates and a limited number of 3DL finishes.

- Customizable finishes and sizes

Product Details

Design your own custom café square tabletop- 30 HPL and 10 3DL choices. HPL top is 1 1/8” particleboard core with high pressure laminate (HPL) top surface and moisture resistant bottom surface with a protective T-mold or 3mm edge. 3DL top is 1”th MDF core, 14 mil vinyl film heat pressured glued sealing top and edge surface; bottom surface is sealed TFL. Edge is seamless, part of top. Barricks stocks 30 HPL and 10 3DL options to create your customized design. Now, choose your accompanying base. Barricks stocks a variety of cast iron base styles in round, pedestal base or 4-point base.

Café Top Series- Square

HPL Top Particleboard Core

| Size | T-Mold Model # | 3mm Model # | Weight |

| 30×30 | ATSE-30SQ-PT | ATSE-30SQ-PM | TBD |

| 36×36 | ATSE-36SQ-PT | ATSE-36SQ-PM | TBD |

| 42×42 | ATSE-42SQ-PT | ATSE-42SQ-PM | TBD |

| 48×48 | ATSE-48SQ-PT | ATSE-48SQ-PM | TBD |

3DL Top MDF Core

| Size | 3DL Model # | Weight |

| 30×30 | ATSE-30SQ-3D | TBD |

| 36×36 | ATSE-36SQ-3D | TBD |

| 42×42 | ATSE-42SQ-3D | TBD |

| 48×48 | ATSE-48SQ-3D | TBD |

Specification & Materials

Top:

HPL Particle Board Core- 1 1/8″ th particleboard core with high pressure laminate (HPL) top surface, moisture resistant backer bottom surface finished with a protective edge option- t-mold or 3mm.

3DL MDF Core- 1″ th MDF core with 14 mil vinyl film heat pressured glued sealing MDF top and edge surface- no seams; bottom surface is sealed TFL.

Edging:

T-mold- an extruded plastic edging in the shape of a “T”. The stem part is barbed and inserted into a slot in the core board. The friction barbs prevent the t-mold from coming out of the core. T-mold external surface is slightly rounded and provides protection against impacts to side. T-mold is an economical edge.

3mm- An extruded 3mm (1/8”) plastic that is machine glued to panel sides sealing edge, then machine trimmed to fit panel thickness. Edging provides protection against impact to sides. 3mm corners are square and more expensive than using T-mold.

3DL- Incorporated as part of top, seamless.

Assembly

Secures to base using its instructions/hardware.