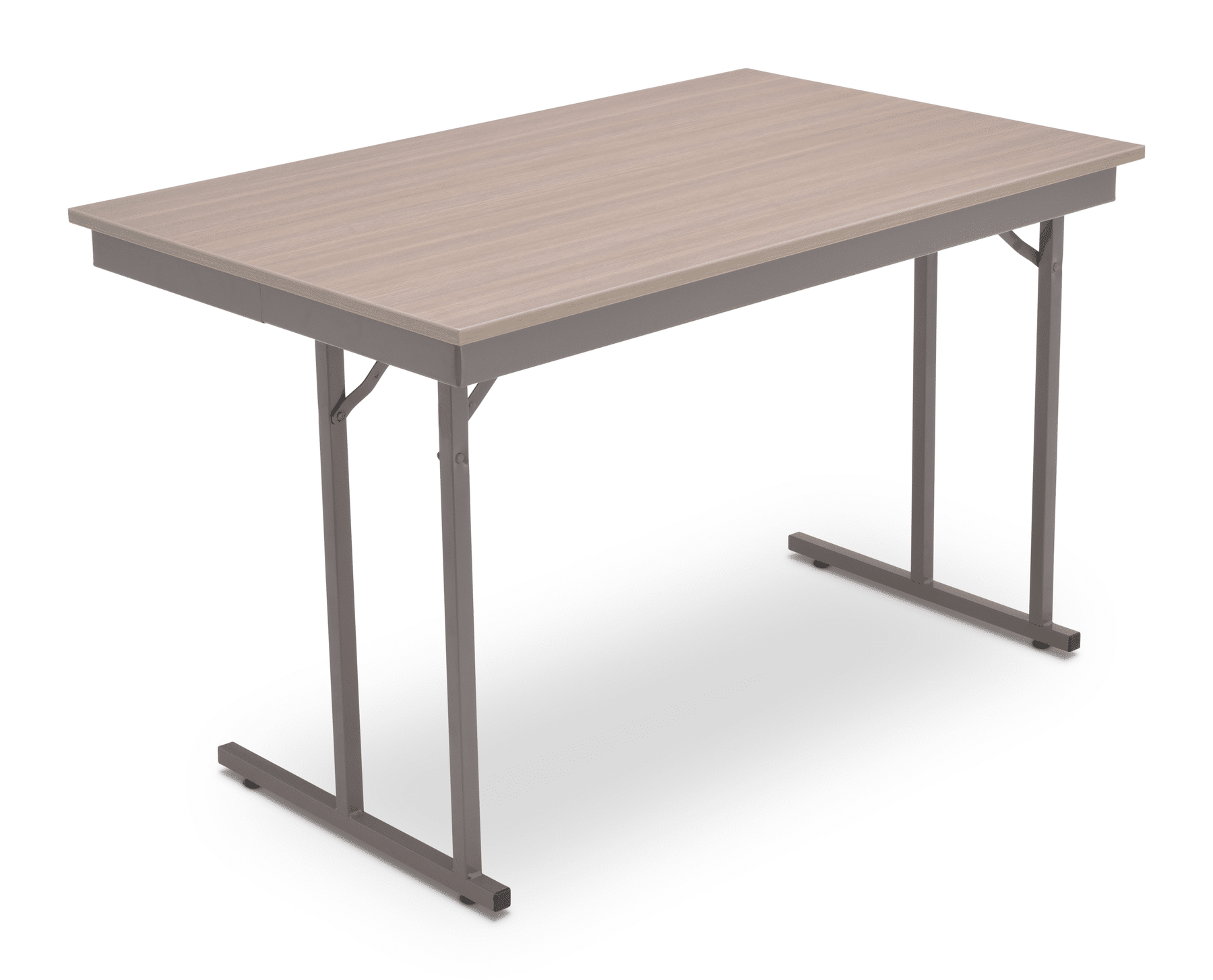

4600 Series

Call for Price

Computer Table with Modesty Panel

- Adjustable height economical workstation

- Standard height adjustment 26”- 30”h; custom height adjustment available to meet individual needs

- Six standard sizes, largest 30”W x 72”L

- Modesty panel grommets standard

- Double C leg provides exceptional leg clearance

- 1 ¼” top available in HPL laminates; 30 stocked selections plus custom option

Product Details

Barricks 4600 series table’s six sizes provides multiple work surface area options. Height adjustability with custom options matches individual needs. The top is 1 1/8” particleboard core with high pressure laminate top surface and moisture resistant bottom surface with a protective t-mold or 3mm edge. The 4600 Series leg standard adjustment is 26”-30” and has upper and lower sections. The upper section has two 1 ¼” sq 18 gauge steel supports welded to 1 1/4” sq 18 gauge steel top support bar. Lower section is 1 x 2” 18 gauge steel base bar welded to two 1 1/8” sq gauge vertical supports. Steel modesty panel secures to each leg. Adjustable levelers ensure proper height positioning and alignment on uneven floors. Barricks stocks 30 HPL options to create your customized design.

4600 Series- 26-30″ Height

HPL Top Particleboard Core

| Size | T-Mold Model # | 3mm Model # | Weight |

| 24×30 | BK46-2430-PT | BK46-2430-PM | TBD |

| 24×48 | BK46-2448-PT | BK46-2448-PM | TBD |

| 30×36 | BK46-3036-PT | BK46-3036-PM | TBD |

| 30×48 | BK46-3048-PT | BK46-3048-PM | TBD |

| 30×60 | BK46-3060-PT | BK46-3060-PM | TBD |

| 30×72 | BK46-3072-PT | BK46-3072-PM | TBD |

Specification & Materials

Top:

HPL Particle Board Core- 1 1/8″ th particleboard core with high pressure laminate (HPL) top surface, moisture resistant backer bottom surface finished with a protective edge option- t-mold or 3mm.

Edging:

T-mold- an extruded plastic edging in the shape of a “T”. The stem part is barbed and inserted into a slot in the core board. The friction barbs prevent the t-mold from coming out of the core. T-mold external surface is slightly rounded and provides protection against impacts to side. T-mold is an economical edge.

3mm- An extruded 3mm (1/8”) plastic that is machine glued to panel sides sealing edge, then machine trimmed to fit panel thickness. Edging provides protection against impact to sides. 3mm corners are square and more expensive than using T-mold.

Legs:

4600 Series leg standard adjustment is 26”-30” and has upper and lower sections. The upper section has two 1 ¼” sq 18 gauge steel supports welded to 1 1/4” sq 18 gauge steel top support bar. Lower section is 1 x 2” 18 gauge steel base bar welded to two 1 1/8” sq gauge vertical supports. Steel modesty panel secures to each leg. Adjustable levelers ensure proper height positioning and alignment on uneven floors.

Assembly

Need assembly PDF